E-mail: [email protected]

E-mail: [email protected]

20+

with over years of experience

Advanced equipment

Excellent Techonlogy

JingHang Engineering Plastic Manufacturer. Every piece of product( including material , technology and production) , they are all achievements of engineers. Jinhang adopts 5S modern management system , thus pushes the management to be more initiative and creative. The research center ,which consists of material engineer , process engineer and mechanic , is full of cooperative , votive and elaborate.

Thanks to the hard-working workers, modern production equipment and strict quality control management system , Jinhang becomes a powerful competitor in this industry…

Professional experience

More than 20 years of production in engineering plastic industry, with the leading technology.

Reliable quality assurance

With ISO quality management system and technical quality control team.

Competitive prices

Manufacturers direct, no middlemen ,to give you the best price.

Products customizable

With professional personnel and advanced technical support.

Today, on this special day that carries historical glory and national pride, the ultra-high molecular weight polyethylene sheet production enterprise organized all employees to collectively watch the grand 9.3 Victory Day military parade, solemnly and warmly remembering history, paying tribute to heroes, promoting patriotism, and inspiring team cohesion and industry mission. In the morning, the…

In today’s increasingly widespread application of nuclear technology, innovation and development of radiation protection materials have attracted much attention. Recently, a new composite shielding material combining polyethylene matrix and boron element – boron containing polyethylene sheet, has become the focus of discussion among industry experts due to its superior performance in neutron radiation protection. Neutron…

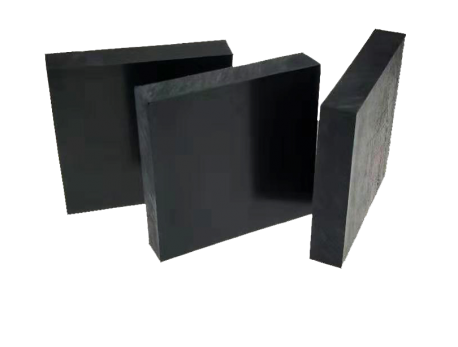

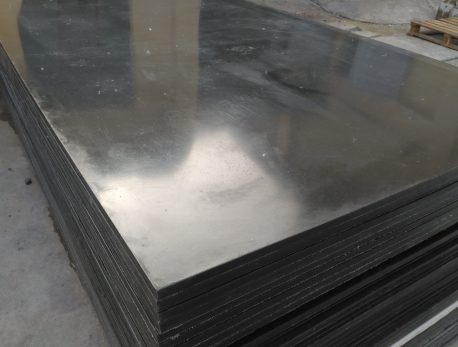

Recently, our company successfully completed a major shipment task. We packed and shipped 230 anti-static UPE boards efficiently. This achievement not only demonstrates our company’s efficient workflow and team collaboration ability, but also proves our position in the industry again. As a kind of high-performance material, anti-static UPE board is widely used in the industrial…

In the golden autumn of October, on the National Day holiday, the mountains and rivers are magnificent and the years are extraordinary. On this day of universal celebration, all the staff of Henan Jinhang, with extremely excited feelings, send the most sincere blessings to our motherland. Looking back at the development process of our enterprise, we feel extremely proud. In the embrace of our motherland, we have thrived and continuously made innovations and breakthroughs. From a small enterprise, we have developed into a leader in the ultra-high molecular weight polyethylene products industry. This is inseparable from the support of our motherland and the efforts of all the staff. The enterprise has always been committed to the development of its staff, providing them with promotion channels and diversified development opportunities. The staff have found their own value in the enterprise and realized their dreams. We have achieved mutual success, grown together, and strived for the future of Henan Jinhang. We have always adhered to the customer-centered approach and continuously improved the quality and service level of ultra-high molecular polyethylene products. Through continuous technological innovation and management optimization, we have provided customers with more efficient, convenient and high-quality solutions. At the same time, we have also actively expanded domestic and foreign markets, strengthened exchanges and cooperation with domestic and foreign partners, and continuously enhanced the international competitiveness of the enterprise. While the enterprise is developing, we also always keep in mind our social responsibilities. We actively participate in public welfare undertakings, care for disadvantaged groups, and make our own contributions to social harmony and stability. We deeply understand that only when the country is prosperous and strong can enterprises develop sustainably; only when the society is harmonious and stable can the people live happily and peacefully. On this special day, we will continue to carry forward the spirit of hard work and innovation, keep forging ahead, and contribute our own strength to the prosperity and strength of our motherland. Let us jointly wish our motherland more prosperity and the people a better life!