E-mail: [email protected]

E-mail: [email protected]

04-01-2025

04-01-2025

In the daily operation of modern slaughterhouses, the health and safety of the trench system has always been the concern of managers. The traditional metal or concrete trench cover plate has been facing the problems of corrosion, slip risk and high maintenance costs for a long time, while the appearance of polyethylene trench cover plate…

03-31-2025

03-31-2025

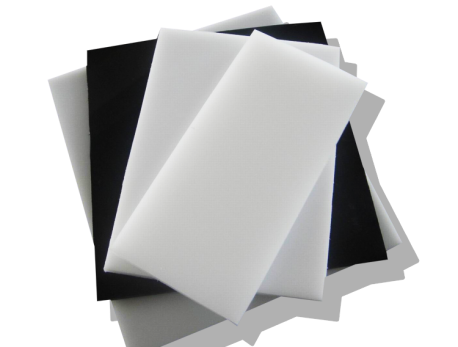

In the vast world of the industrial field, the smooth operation of each link is related to production efficiency and cost control. And our polyethylene polymer wear-resistant board, with its incomparable advantages, has become many enterprises to improve the efficiency of the right-hand man. Polyethylene polymer wear resistance board, using advanced technology and high-quality raw…

03-26-2025

03-26-2025

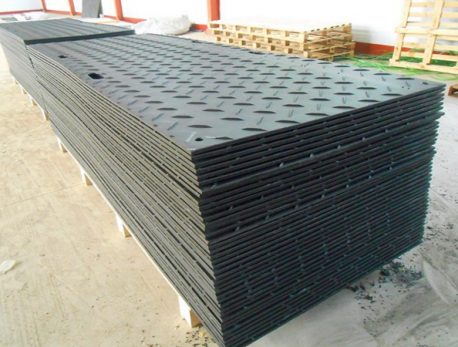

In busy construction sites, muddy roads often become “obstacles” to the construction progress. Vehicles fall into the mire and workers walk hard, which not only delays the construction period, but also increases the safety risks. Traditional solutions including laying gravel and using a mixture of sand and soil have limited effect, and with the advances…

03-25-2025

03-25-2025

In the face of muddy and soft ground conditions, heavy machinery and equipment often struggle, like trapped in an endless mire, seriously slowing down the progress of the project. However, the introduction of polyethylene road substrate has brought a turnaround for this dilemma. Polyethylene road substrate with its material advantage, showed an extraordinary adaptability. Whether…

03-21-2025

03-21-2025

The core component of papermaking machinery —— suction tank cover plate plays a vital role in modern industrial production, suction tank cover plate is made of polyethylene, outstanding wear resistance, even in a long working environment, it can maintain the integrity of its surface, not easy to wear and damage. At the same time, the water absorption…

11-21-2024

11-21-2024

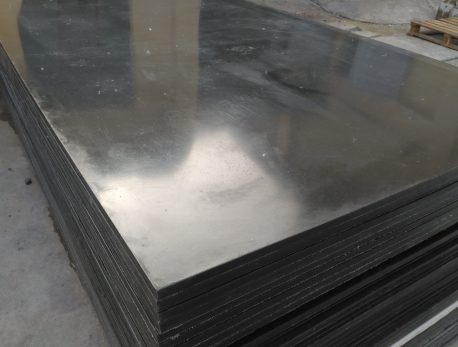

The efficient operation of grain machinery is inseparable from high-quality materials, and polyethylene sheet is one of the outstanding ones. In grain storage equipment, polyethylene sheet can be used to make the inner lining of the chute. Due to its smooth surface, the grain descends evenly in the chute and is not prone to blockage, avoiding equipment damage and potential safety hazards caused by grain accumulation. In grain cleaning equipment, such as the sieve plate of a vibrating screen made of polyethylene sheet, it can efficiently screen impurities while reducing damage to grain particles and ensuring the integrity of the grain. Its impact resistance enables it to withstand the impact force when the grain is fed and operate stably. The moisture-proof performance of the polyethylene sheet helps maintain a dry grain storage environment and prevent grain from getting damp and moldy. In the grain processing stage, such as the internal lining plate of a flour mill using this sheet, it can reduce noise pollution and provide operators with a relatively quiet working environment. Its environmental protection characteristics meet the requirements of modern grain industry for sustainable development. It is non-toxic and odorless and will not cause secondary pollution to the grain. It can be said that the polyethylene sheet provides strong support for the optimization and upgrading of grain machinery from multiple perspectives, promoting the grain industry to move towards a more efficient and higher-quality direction.